Machine Sazi Arak (MSA) with more than 40 years of experience in modem industries, technology and technical/engineering services has always played a leading role in reinforcing the country's industrial capabilities and developing, promotion and transfer of modern technologies. MSA Machining and Assembling Production Group, enjoying modem machineries, advanced production lines and experienced engineering staff, various forging, casting and machining and test shops produces different types of, wellhead equipment, and valves used in oil, gas and petrochemical industries as per the latest internationally renowned standards. Advanced secondary steel making facilities such as VODC (vacuum oxygen decarburization convertor) are employed for producing the required raw material (carbon steel, low/high alloy steel and stainless steel).

The materials for valves and wellhead equipment are as per: API 6A and NACE MR 0175 standards. Mechanical properties, metal structure stability, corrosion/ erosion and scaling resistance in different temperature and pressure conditions are guaranteed through adherence to above standards & controlling procedures such as appropriate heat treatment cycles, mechanical& hardness tests, radiography, ultrasonic and hydro test.

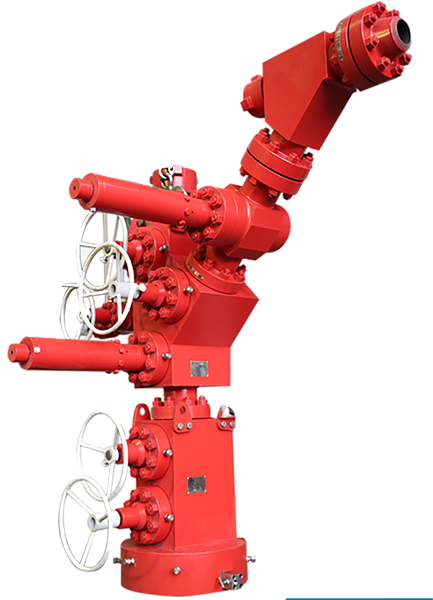

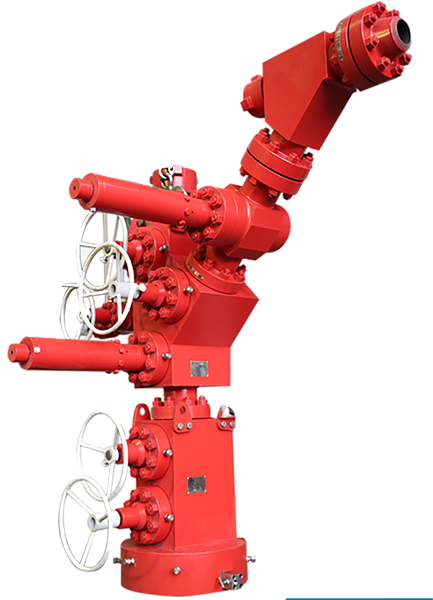

Products of MSA Machining and Assembling Production Group (Click to see)

Group Capabilities for heavy duty machining

Machine Sazi Arak, enjoying skilled/experienced workforce, CNC machines and high precision heavy duty machine tools, is capable of accomplishing projects such as machining main parts of hydro-electric turbines including head cover, bottom ring, rotor hub and machining high diameter rings and flanges up to 57".

Specifications of some heavy duty machine tools of Machining and Assembling Production Group:

1) Vertical turning/milling CNC Machine

- Max. Work piece weight: 100 tons

- Max. Work piece diameter: 12m

- Max. Work piece height: 4.7m

- Machining precision: 0.01mm

2) Horizontal boring CNC machine

- Max. Work piece weight: 12 tons

- Max. Movement of the 3 spindles: 3×3×2.5m

- 4-spindle control

- Machining precision: .01mm

3) Heavy duty turning machine (TP 800)

- Max. Work piece weight: 10 tons

- Max. Work piece length: 8m

- Max. Work piece diameter: 1600mm

- Machining precision: 1mm

4) Gantry milling machine

- Max. Work piece weight: 50 tons

- Distance between the columns: 2.4 m

- Bed dimensions: 2.25×4m

- Max. Horizontal movement: 8.5m

- Max. Vertical movement: 2.5m

Download our catalogue for more detailed information

|