Dena petrochemical industries and Siraf energy Petrochemical Equipment (Methanol plant, capacity of 5000 tons per day)

For the first time in Iran, the contract of delivery proprietary items in Methanol projects has been signed with Machine Sazi Arak. This equipment has been fully supplied from abroad so far but due to the technical knowledge and existing capabilities, has been awarded to Machine Sazi Arak

The contract of proprietary equipment include of following three packages with the scope of mechanical design, thermal design, Finite element analysis, raw materials procurement, manufacturing, test and delivery.

Methanol Reactor

MP Steam drum Secondary Reformer Waste Heat Boiler

Hot Steam super heater

Cold steam super heater, ...

These packages includes 24 special equipment with varieties of materials, including high strength steels, Cr-Mo, nickel based alloys, two phase stainless steel, piping, refractory and burners. Manufacturing of equipment is in form of two separate contracts between Machine Sazi Arak and Dena petrochemical industries and Siraf Energy Petrochemical companies. By entering this field, in addition to meet the need for the current projects and preventing the import of this equipment, the technical knowledge and facility of Machine Sazi Arak has been upgraded.

Morvarid Petrochemical Distillation Tower

Weighing approximately 195 tons with a diameter of 3 meters and a height of 70 meters, which has been delivered to the employer in less than 3 months and shorter than the contract time.

Design, supply of materials, construction and delivery of Gachsaran Petrochemical Tower

Weight 160 tons, diameter 7 meters and length 35 meters

De-Ethanizer Tower of Kangan Petroleum Refinery Project

Internal diameter 5800mm and length 39000 mm and thickness 54mm and weight 320 tons

Distillation towers of Arian D-Polymer Petrochemical (Assaluyeh) methanol design

Weight 233 tons, length 24 meters, diameter 4 meters Weight 136 tons, length 40 meters, diameter 4.5 meters

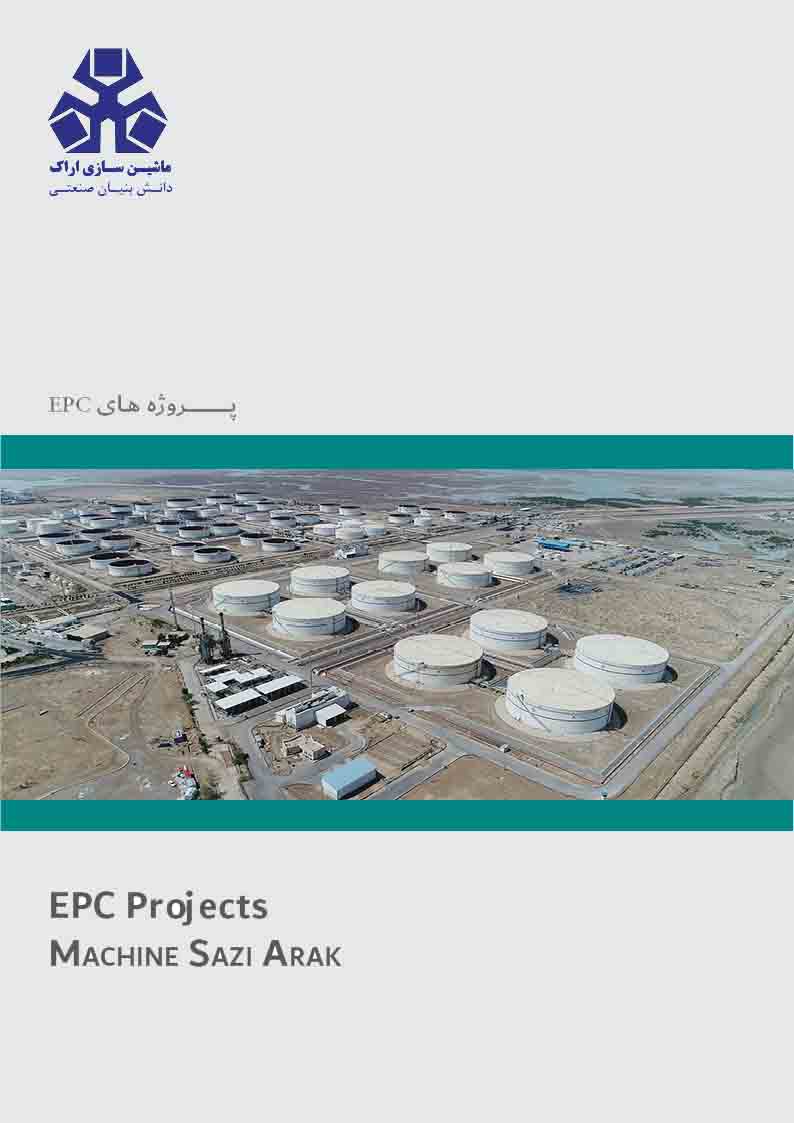

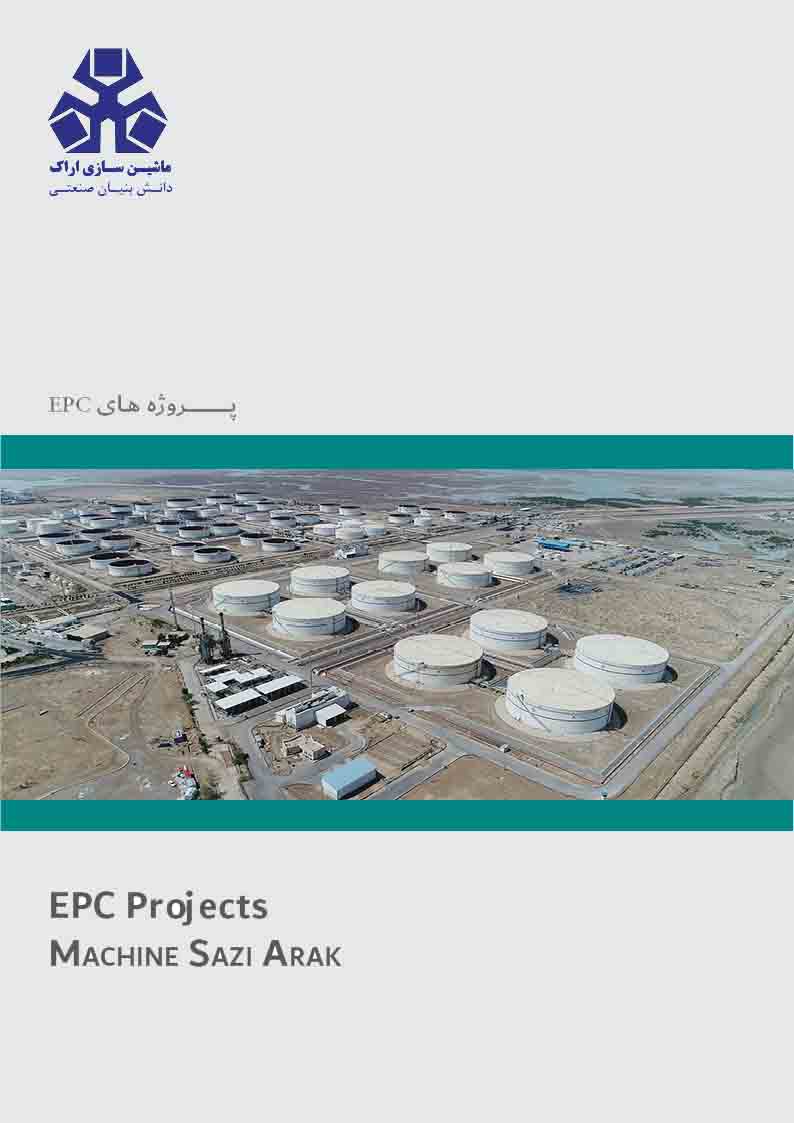

EPC Projects

Mahshahr Export Port Project

The plan of Mahshahr Export Port was handed over to Machine Sazi Arak , Khatam-ol-Anbia and Rampco companies via National Iranian Oil Products Distribution Company as the owner of project in three parts of land, offshore and pipelines in the form of three EPC projects.

The project site of the Mahshahr Export Port is located at a distance of 11 kilometers from Imam Khomeini port and has 6 berths for loading oil products. Products distributed from this port include gasoline, gasoline, petrol, oil, aromatics and naphtha. The engineering phase of this project involves basic, detailed and executive engineering in all engineering disciplines such as civil, mechanics, piping, electricity and telecommunications, instruments and safety. Due to the necessity of port service, the important point in designing this project is design of the project in such a way that, while optimizing the systems, the existing systems of port was fully used. In this project, the basic engineering documents and engineering technical documents for procurement and construction with number of 2700 documents were produced and were approved by the employer. Also about 700 companies were used by domestic and foreign manufacturers to supply the equipment.

In this project, 32 hectares of Majidieh logs were digested and dried then recovered by soil and water so consolidated up to 95%. Equipment for the export of fuel oil and gasoline and bunkering of fuel oil in this section was designed, supplied and installed.

The outline of the EPC works done in this project is as follows:

Engineering and implementation of protection dikes:

Engineering and implementation of protection dikes to cut off seawater with an area of 1200 m and an altitude of 3+ m above the surface of the area

Gasoline storage tanks:

Construction and installation of five 100,000 barrels floating roof tanks for storage of gasoline

Land extraction from the sea of 32 hectares and pre-loading with soil and water

The extraction operations in this project were carried out using drainage and loading procedures. In order to implement vertical drainage, the special towers were used which two of these towers were first made in Machine Sazi Arak in Iran. In addition, to load the soil to consolidate the land, more than 1.5 million square meters of soil was used, with loading height in some places reach to 12 meters, and to accelerate the time and lack of sufficient soil, part of the area 4 units of fixed roof tank were loaded with water of 250 barrels. Previous experience has shown that preloading with soil has more costs in addition to time. It seems that pre-loading method with water be an appropriate alternative to the soil. In this method, after the construction of the tanks, they were continuously and daily stored for 45 days and after a month of storage of water in the tanks, evacuation was carried out.

Gasoline and fuel oil storage tanks:

Construction and installation of twelve 250,000 barrels fixed storage tanks for storage of fuel and gasoline

Transferring water:

Construction of the 8-inch water pipeline with length of 11 km

Piping:

The collection of old pipelines and the implementation of new pipelines in the export port with a volume of more than 400,000 dia/inch and at the same time maintenance of port servicing

Power line:

Construction of KV 132 transmission line to Mahshahr Export Port and construction of KV33 / 132 power station

Substation:

Development of 132/400 kV power supply

Fire extinguishing system:

Design and implementation of a fire extinguishing system including the procurement of tank fire fighting and piping operations

Terminal control system:

Design and manufacture of the largest control system of oil terminals in Iran (DCS & ESD), which is the largest control system designed for oil terminals in Iran, to fully control and automate all oil exports and imports

Electrical Equipment:

Installation of electrical equipment and construction of substations for power transmission and distributi

Building:

Construction of 11,000 square meters of building including industrial buildings (control room, substandard) and non-industrial and service buildings (restaurant, guest house, fire department) construction of 13 kilometers of highways and roads within the boundary of the export port, execution foundation and Band walls and landscaping and surface water collection System

.jpg) .jpg)

Engineering, Procurement and Construction of Karun 4 Bridges

This bridge is the largest arch bridge in the country for connecting the Izeh road to Shahrekord and installed on the reservoir of the Karun 4 dam. Engineering, procurement of raw materials, construction and installing parts and commissioning of this bridge was carried out by Machine Sazi Arak Co. within 20 months. The bridge is arched from below and is constructed as a leading nose on both sides.

Owner: Iran Water and Power Resources Development Company

Project Overview:

Bridge type: Arch

Deck Type: Orthotropic

Deck length: 380 meters

Arc span: 300 meters

Arch deflection: 70 meters

Deck width: 11.8 m

Weight: 3800 tons

Engineering, Procurement and Construction of Karun 4 Cable Stayed Bridges for Oil Pipeline

This project includes engineering, procurement, construction and commissioning of a large cable stayed bridge with a length of about 380 meters on the Karun 4 dam for passage of oil and gas pipelines which was carried out by Machine Sazi Arak Co. within 18 months

Owner: Iran Water and Power Resources Development Company

Project Overview:

Bridge type: Cable Stayed

Deck Type: Orthotropic

Total length of the bridge: 380 m

Width: 9.2 m

Weight of deck and pylons: 1900 tons

Weight of cable: 100 tons

The bridge is currently considered a major bridge in the country, which will be used in nomadic seasons. A large amount of landfill and transshipment operations were carried out to construct the bridge and transport pipelines, and about 19 km of access roads were built.

Borzoueh Petrochemical

MSA activities in Borzoueh petrochemical are as follows: civil and structure activities and engineering, procurement and construction of 6 spherical tanks with capacity of 9000 m different capacities and 4 fixed roof storage tanks and 8 floating roof storage tanks including piping ,firefighting, mechanical equipment(pumps, drums, thermal transformers, compressors and etc.), electrical activities, instrumentation and insulation equipment with a total weight of 34000 tons.

South Pars gas field development phase 14 (SPGFD Phase 14)

Employer: National Iranian Oil Company

Project Specifications:

Designing, constructing, installing and commissioning four sea platforms equipped with 44 wells including 2 appraisal wells, 2 vertical wells and 40 development wells. These platforms also provide sewage water separation facilities along with gas from platforms and MEG injection and other related equipment.

Design, implementation and commissioning of two 32-inch marine pipelines to connect the platforms to the refinery with length of 211 km.

Machine Sazi Arak Co. as one of the members of the Consortium Phase 14 of the South Pars gas field development project, with a contract with a value of US$ 240,000,000 with a share of 4.57 % of the total plan, was responsible for providing the fixed equipment of the refinery.

The scope of work of Machine Sazi Arak Co. includes construction engineering (after receiving mechanical data sheets), the provision of raw materials of various types of sheets, pipes, profiles, forging, fittings and etc., the construction of a workshop of equipment and shipment

Construction engineering, raw material v, construction workshop, transportation and delivery of 165 tanks.

Engineering, construction, material procurement, construction workshop, transportation and delivery of 40 towers.

Construction engineering, raw materials procurement, construction of a workshop, transportation and delivery of 16 reactors.

Engineering, construction, material procurement, workshop, transportation and delivery of 81 heat exchangers.

Engineering, manufacturing, supplying, manufacturing workshops, shipping and delivering 52 aircrafts

Contractor: A consortium of 8 members with the leadership of IDRO is as follows:

1. Iranian Industrial Development and Renovation Organization (Consortium Leader) - (IDRO)

2. Iranian Offshore Engineering and Construction Company (IOEC)

3. Iran Industrial Project Management Company (IPMI)

4. Iranian Offshore Shipping and Offshore Industrial Complex (ISOICO)

5. Iran Power Plants Management Company (MAPNA)

6. Machine Sazi Arak (MSA)

7. Iranian National Drilling Company (NIDC)

8. Paybandan Co.

Mahshahr Export Port Supplementary Project - Sulfur Port (EPC)

The project aims to construction, installation and commissioning of facilities equipment and machineries for storage, and the annual export of 1,000,000 tons of produced sulfur granules in refineries of National Iranian Oil Company (NIOEC)

The description of Machine Sazi Arak's services includes all design and engineering activities, procurement, construction, installation, execution, technical inspection, commissioning and final delivery.

In this regard, after conducting studies and geological experiments and preparing land improvement methods, the design and engineering of facilities and structures such as the bascule, drainage station (hopper) and sulfur storage facility as well as the transmission machinery including feeders, systems conveyor and weighing containers and related structures, tripper car, reclaimer, and ship loader, as well as electrical and instrumental equipment and central control system, buildings, installations and ventilation, lighting, and cathodic protection, etc. is done. According to safety considerations and environmental issues such as fire extinguishing systems and dust collectors and others.

After the construction and equipping of workshops, due to the financing problems in Oil Ministry, who is the owner of project, the project has to stop.

EPC Projects Catalogue

|

.jpg)

.jpg)